In the last few years, MolGen helped laboratories in scaling up testing capacity with their high-throughput workflows. A vital piece in these workflows has been the PurePrep TTR, a high-throughput tube transfer system that can process up to 320 samples per hour. The system has proven itself to be highly reliable through various projects and applications, however some of our clients find it challenging that the system lacks flexibility in handling various tube sizes.

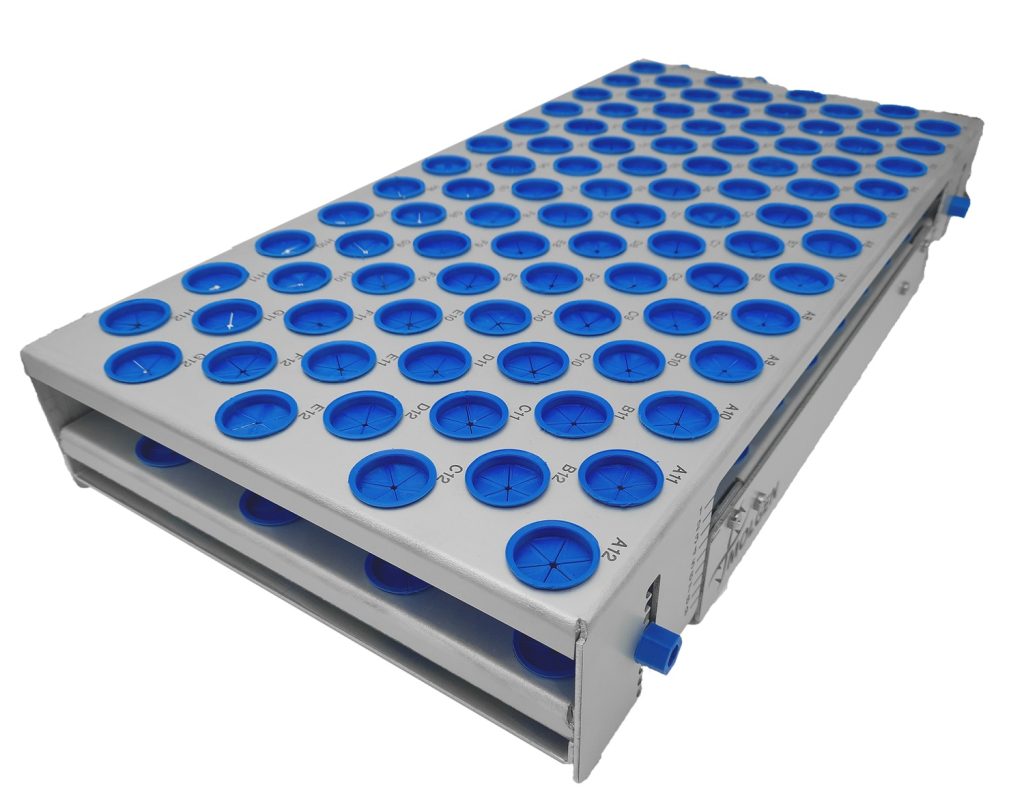

Our Technical Application Specialist Bastiaan Ebbelaar set out to fix this by creating the T-Rack; an intuitive tube rack for the PurePrep TTR that can easily be adjusted to handle a wide range of industry standard tubes.

How The T-Rack came to be

Initially, the PurePrep TTR was designed and set-up with a standard tube rack to process our PurePrep TL+ 15 mL tubes. If a client then had three different tube sizes, three different tube racks would also have to be developed to meet their needs. With design, prototyping, testing and development this could easily take up to an additional three to four weeks to be finished.

While at MolGen we were already ideating possible solutions to this issue, we got a request from a client based in New York with two PurePrep TTR systems. They claimed to have four different tube types to process. To help this client, the development of the T-Rack got started. We ended up working with the company Alles in 3D who collaborated at various stages in the development of the T-Rack such as development and prototyping.

Features

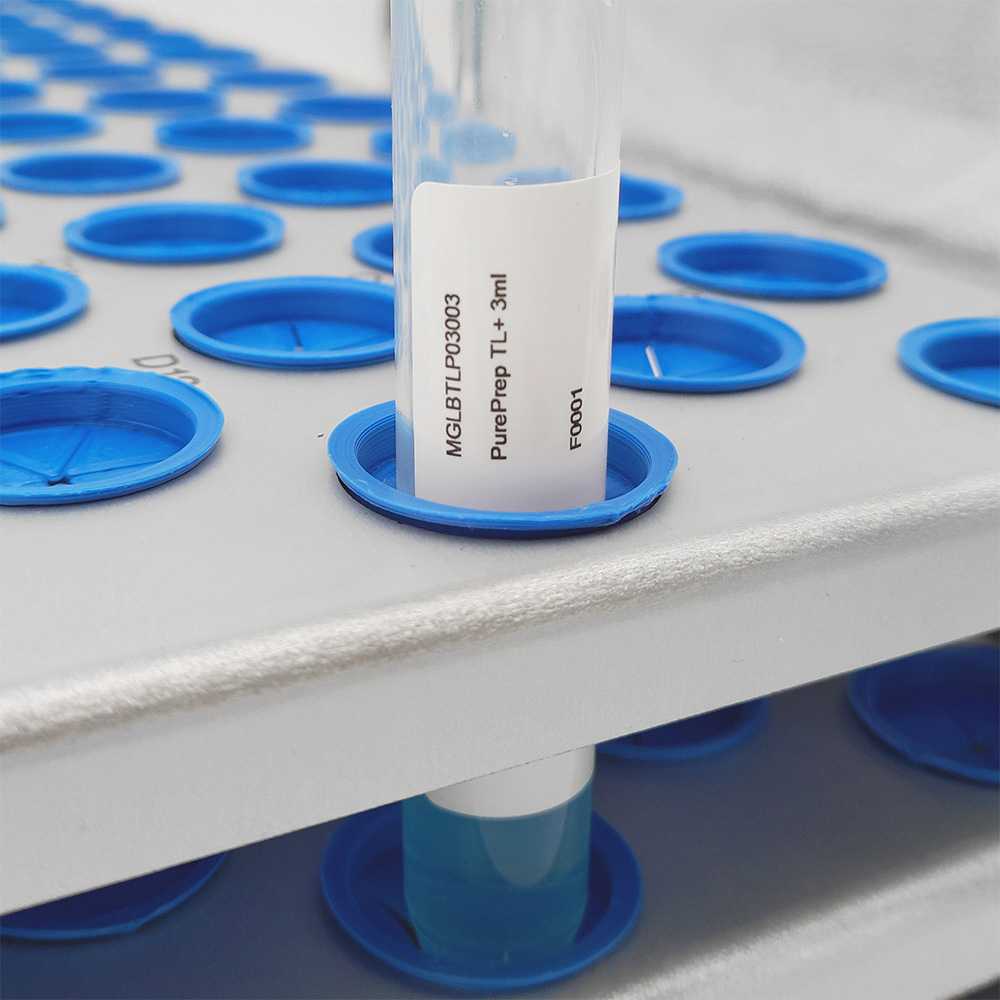

Polymer Inserts

The design went through various stages: first simply being a rack with polymer inserts. The polymer inserts were a stroke of inspiration at a fast-food restaurant near our HQ office when we took note of the + shaped holes in the lids of milkshake cups. We recreated a hole like this with silicon which proved to be a troublesome material, but after switching to polymer the T-Rack provided greater stability to a significant percentage of industry standard tubes.

Adjustable Height

The first version was not adjustable in height, causing problems for the stability of longer tubes. We returned to the drawing board and created a few iterations of racks with adjustable heights, eventually ending up with an extremely versatile accessory for the PurePrep TTR.

We also opted to have the rack made of aluminium instead of stainless steel. This reduction in weight makes it significantly easier to carry, an important benefit for lab employees.

MolGen is always looking to support their customers by providing the ideal solutions, even if they are custom-made. Are you interested in a T-Rack or a different custom solution? Feel free to contact us to discuss possibilities.